6 Applications of Epoxy Floor Coating and How to Get It Right

Before we get into the nitty-gritty of where you can use epoxy floor coating, let's have a quick look at what epoxy coating is and why you should choose it.

Hardeners and resins are the two components of epoxy coating which, when combined, forms a rigid epoxy material due to a chemical reaction.

When this epoxy material bonds with the substrate, a strong coating is formed which guards the concrete against chemical and mechanical wear.

Epoxy coating provides a sealed and hygienic floor surface in addition to a number of benefits like durability, strength, low maintenance, aesthetics, chemical resistance, safety, brightness and much more. This is why epoxy floor coatings are so popular today.

Where Can You Apply Epoxy Floor Coating?

With a range of colours and designs, there is a considerable scope of usage when it comes to epoxy floor coatings. As it is flexible, you can request bold colours. It all depends on what you want. The popular colours that are used in its application are a range of grey scales, reds, greens and blues.

Commercial Applications

Epoxy floor coating is an economical option and because of its qualities, it has become one of the preferred choices for commercial use. The best part is; it can be applied quickly so there is limited downtime.

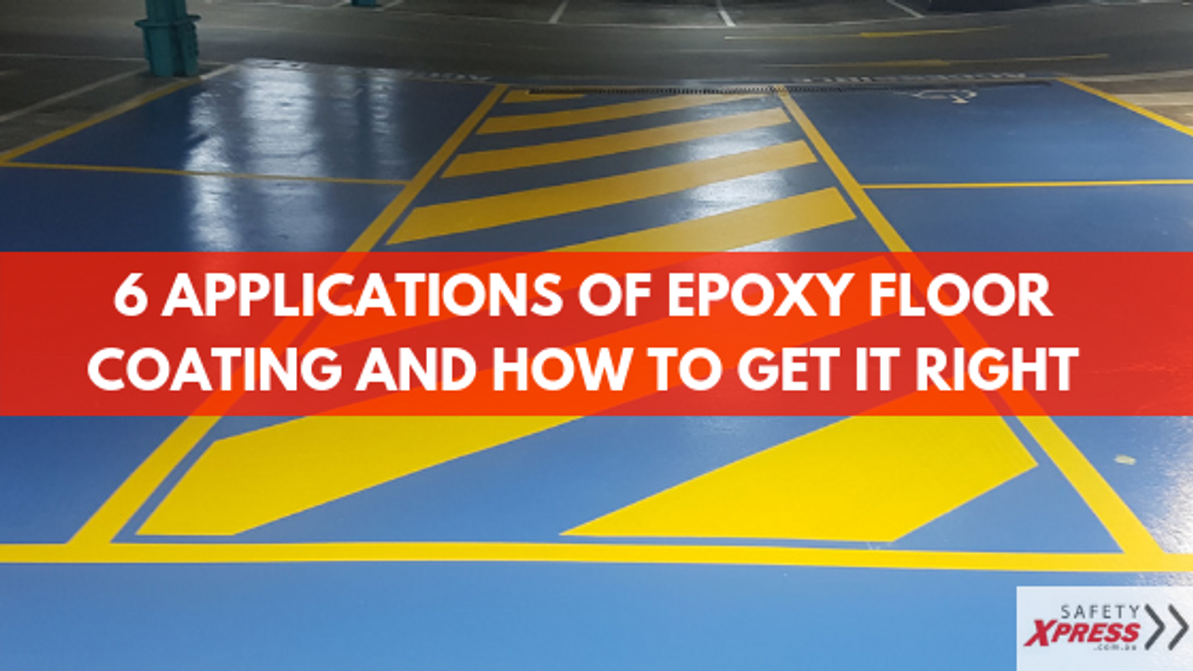

1.Epoxy Floor Coating For Undercover Carparks

Nothing looks better than a well finished epoxy floor on undercover carpark surfaces. This can be achieved by applying a hard-wearing epoxy finish with non-slip aggregate added in potentially slippery areas. The epoxy coating finish is ideal for a paint application to be applied after, to provide designated parking spaces. Parking spaces can have a colourful epoxy applied complete with symbols in paint, for instance Disabled (Blue), Parents with Prams (Pink), Seniors (Yellow), Electric Charging Bays (Green) etc.

2.Epoxy Floor Coating for Warehouse and Industrial Units

Concrete in warehouses could lead to a number of potential problems. Dust, stains from spills and oils, dirt and grime can penetrate the concrete and leave nasty, ugly remnants. Using an epoxy floor coating can solve these issues.

It is recommended that you consider the traffic of the area before choosing the coating for your industrial unit, factory or warehouse. The epoxy floor coating is well suited to be applied in fast-paced environments and heavy traffic areas.

You could choose an epoxy floor coating to segregate specific areas like a pedestrian walkway, designated bike lane, pallet storage and forklift movement areas. This can enhance your safety measures by keeping pedestrians and vehicles in clearly defined areas also providing a highlighted awareness between the two.

3.Epoxy Floor Coating for Offices

Offices could consider using epoxy floor coatings. After all, the surface would be highly durable and provides bold aesthetics with a range of colours and finishes. The big upside is that the epoxy floor coating is easy to clean and maintain.

4.Epoxy Floor Coating for Gyms

It is a popular choice for gyms because of the qualities like slip-resistant, easy to clean and above all, enhancement of an otherwise boring concrete floor. You can even create a strong visual identity for your gym floor by using gloss colour and attractive design options. This could include segregating certain exercise areas.

Residential Applications

Not only in commercial, but even in residential properties you could apply epoxy floor coatings. Although, it is highly recommended that it is by specialist applicators.

5.Epoxy Floor Coating for Kitchens

When we talk about kitchens, we talk about hygiene. The anti-microbial additives in epoxy coatings can make your kitchen more resistant to germs and bacteria. It can even become easier for you to sanitise. Additionally, it has anti-slip properties and can withstand high temperatures as well as oil spills.

6.Epoxy Floor Coating for Garages

A garage is a place where you will often find different chemicals, oil, petrol, cleansers and transmission fluids. Well, epoxy is resistant to all of them. But before applying the epoxy floor coating, be sure that the floor contaminations are removed. Where higher protection may be required, it is recommended to use a primer followed by two coats of epoxy.

How to Apply Epoxy Floor Coating?

Application of epoxy coatings can be is quite simple

and anyone with DIY skills may be able to carry out this application. But, when

you need a seamless high-specification finish, it is best to seek professional

assistance.

Epoxy resin does not level up on its own. It is best to prepare the floor first and then apply the epoxy coating with two coats for a high-quality seamless finish.

Below are the steps that you need to follow to apply epoxy floor coating:

Preparing the Surface

Step: 1 Prepare the Surface Area

This is required to ensure adhesion between the epoxy product and the substrate. Opt for sanding or grinding especially in the case where surfaces have been contaminated with oils.

Step: 2 Clean and Sweep the Floor

Clean even the smallest dust particles with an industrial vacuum. In short, the floor must be thoroughly cleaned before you start priming and, or coating. Or else, various particles will be trapped within the coat which can further weaken the adhesion.

Priming and Filling

Step: 3 Prime the Floor with the Epoxy Primer

A primer may give your coating a longer life and better adhesion. To prime, the areas must be properly ventilated. Coat two layers of primer so that the floor is properly sealed.

Step: 4 Fill the Cracks and Holes with Epoxy Grout

Use a diamond cutter to slice any thin cracks or holes before filling. This will improve the anchoring of the grout. Repeat the same process for holes.

Applying the Epoxy Floor Coating

Step: 5 Apply the First Coat

To prepare component A, add the required amount of hardener. Mix the two parts as per the instructions on the container. Poor mixing may lead to a tacky floor so don't skimp with the mixing part!

Step: 6 Apply the Product with a Roller

Use a quality roller for application. Once done, let it dry. The next day, you may notice various imperfections like cracks, or holes which are visible. In this case, prepare them by doing a light grind to smooth before you start with the final coat. You should be able to re-coat after a day, but if required, wait an extra day for the grout where repairs have been applied, to dry completely.

Step: 7 Apply the Final Coat

Once again, before applying the final coat, it is recommended to ensure that all holes and cracks have been filled, all dust has been collected and all the surfaces look even. This will avoid getting you a rough texture. It is good to mix one bucket at a time as most epoxy products have a pot life of approximately 40 minutes.

As mentioned above, it is recommended to hire a professional if you are really looking forward to getting a seamless look. If you are looking for epoxy flooring solutions- we recommend Durasafe. They are our partners and a leading name in this industry. We can vouch for their accurate and quality floor coating solutions. They have a professional team that maintains the Australian standards whilst providing services in a way that will benefit you for the years to come.

If you want more information or want to explore the types of epoxy flooring coatings, call us on 1300 049 246.

Recent Posts

-

EzyRail- The Ultimate Modular Handrail System for Safety & Convenience

Navigating industrial spaces, warehouses, or public areas without proper safety measures can be risk …15th May 2025 -

All You Need to Know About Surface Mounted Bollards- Secure, Flexible & Easy to Install

Looking for a quick and hassle-free way to enhance security and manage traffic? Surface mounted boll …1st May 2025 -

Which Speed Hump For Which Location?

At Safety Xpress, we have 3 types of Australian compliant speed humps. All of which suit different …16th Jul 2021